扫描二维码,快速下载本应用说明文档(免费)

【电子陀螺仪模块】 应用介绍

MPU-60X0 是全球首例9 轴运动处理传感器。它集成了3 轴MEMS 陀螺仪,3 轴MEMS加速度计,以及一个可扩展的数字运动处理器DMP(Digital Motion Processor),可用I2C接口连接一个第三方的数字传感器,比如磁力计。扩展之后就可以通过其I2C 或SPI 接口输出一个9 轴的信号(SPI 接口仅在MPU-6000 可用)。MPU-60X0 也可以通过其I2C 接口连接非惯性的数字传感器,比如压力传感器。

MPU-60X0 对陀螺仪和加速度计分别用了三个16 位的ADC,将其测量的模拟量转化为可输出的数字量。为了精确跟踪快速和慢速的运动,传感器的测量范围都是用户可控的,陀螺仪可测范围为±250,±500,±1000,±2000°/秒(dps),加速度计可测范围为±2,±4,±8,±16g。

MPU6050的用途非常广泛,手机、可穿戴式设备、VR/AR游戏设备等设备都需要用到MPU6050的传感器来读取移动的角速度和角度。

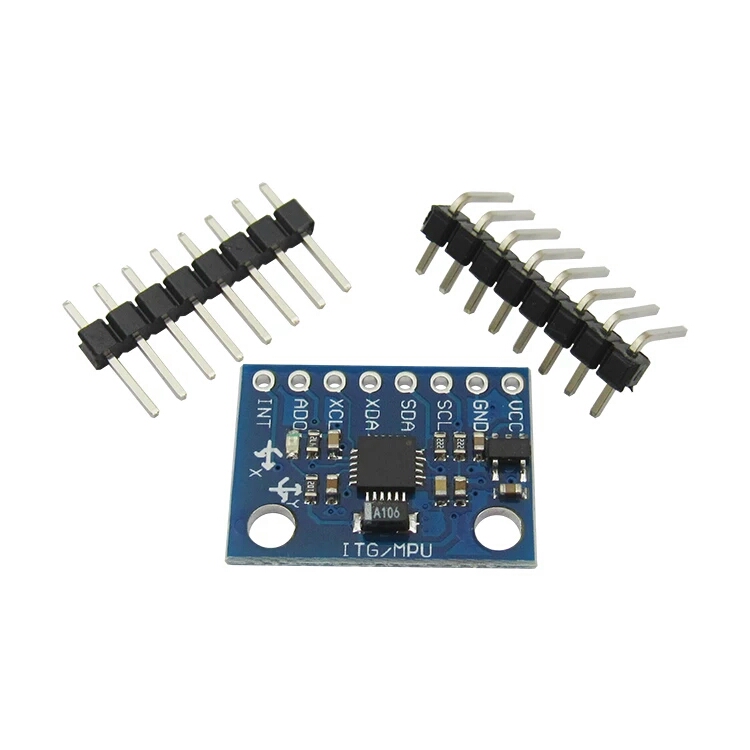

MPU6050的资料图片

首先是定义陀螺仪的数据变量:

#include "I2Cdev.h"

#include "MPU6050.h"

// Arduino Wire library is required if I2Cdev I2CDEV_ARDUINO_WIRE implementation

// is used in I2Cdev.h

#if I2CDEV_IMPLEMENTATION == I2CDEV_ARDUINO_WIRE

#include "Wire.h"

#endif

// class default I2C address is 0x68

// specific I2C addresses may be passed as a parameter here

// AD0 low = 0x68 (default for InvenSense evaluation board)

// AD0 high = 0x69

MPU6050 accelgyro;

//MPU6050 accelgyro(0x69); // <-- use for AD0 high

int16_t ax, ay, az;

int16_t gx, gy, gz;

int axoffs,ayoffs,azoffs;

int gxoffs,gyoffs,gzoffs;

double rgx,rgy,rgz;

double rax,ray,raz;

double ax0,ay0,az0;

double ax1,ay1,az1;

double wx0,wy0,wz0;

double wx1,wy1,wz1;

double dwx,dwy,dwz;

double q0,q1,q2,q3;

double p0,p1,p2,p3;

double qc0,qc1,qc2,qc3;

double roll,pitch,yaw;

double t1;

double t0;

double t;

double dw;

// uncomment "OUTPUT_READABLE_ACCELGYRO" if you want to see a tab-separated

// list of the accel X/Y/Z and then gyro X/Y/Z values in decimal. Easy to read,

// not so easy to parse, and slow(er) over UART.

#define OUTPUT_READABLE_ACCELGYRO

// uncomment "OUTPUT_BINARY_ACCELGYRO" to send all 6 axes of data as 16-bit

// binary, one right after the other. This is very fast (as fast as possible

// without compression or data loss), and easy to parse, but impossible to read

// for a human.

//#define OUTPUT_BINARY_ACCELGYRO

#define LED_PIN 13

bool blinkState = false;

// 然后是打开串口准备接收和发送数据:

void setup() {

// join I2C bus (I2Cdev library doesn*t do this automatically)

#if I2CDEV_IMPLEMENTATION == I2CDEV_ARDUINO_WIRE

Wire.begin();

#elif I2CDEV_IMPLEMENTATION == I2CDEV_BUILTIN_FASTWIRE

Fastwire::setup(400, true);

#endif

// initialize serial communication

// (38400 chosen because it works as well at 8MHz as it does at 16MHz, but

// it*s really up to you depending on your project)

Serial.begin(9600);

// initialize device

Serial.println("Initializing I2C devices...");

accelgyro.initialize();

accelgyro.setFullScaleGyroRange(MPU6050_GYRO_FS_500);

accelgyro.setFullScaleAccelRange(MPU6050_ACCEL_FS_2);

// verify connection

Serial.println("Testing device connections...");

Serial.println(accelgyro.testConnection() ? "MPU6050 connection successful" : "MPU6050 connection failed");

// use the code below to change accel/gyro offset values

q0=1;

q1=0;

q2=0;

q3=0;

getoffs();

// configure Arduino LED for

pinMode(LED_PIN, OUTPUT);

}

// 然后写个函数获取小车角速度和转动角度的数据:

void Readangle() {

// read raw accel/gyro measurements from device

accelgyro.getMotion6(&ax, &ay, &az, &gx, &gy, &gz);

t0=t1;

t1=micros();

t=(t1-t0)/1000000;

// these methods (and a few others) are also available

//accelgyro.getAcceleration(&ax, &ay, &az);

//accelgyro.getRotation(&gx, &gy, &gz);

ax=ax+axoffs;

ay=ay+ayoffs;

az=az+azoffs;

gx=gx+gxoffs;

gy=gy+gyoffs;

gz=gz+gzoffs;

//calibration error

rgx=gx;

rgy=gy;

rgz=gz;

rax=ax;

ray=ay;

raz=az;

wx0=wx1;

wy0=wy1;

wz0=wz1;

//

p0=q0;

p1=q1;

p2=q2;

p3=q3;

//

wx1=rgx/65.5;

wy1=rgy/65.5;

wz1=rgz/65.5;

ax1=(rax/16384)*9.80;

ay1=(ray/16384)*9.80;

az1=(raz/16384)*9.80;

//

dwx=((wx1+wx0)/2)*t*0.01745;

dwy=((wy1+wy0)/2)*t*0.01745;

dwz=((wz1+wz0)/2)*t*0.01745;

//

dw=sqrt(dwx*dwx+dwy*dwy+dwz*dwz);

qc0=cos(dw/2);

qc1=(dwx/dw)*sin(dw/2);

qc2=(dwy/dw)*sin(dw/2);

qc3=(dwz/dw)*sin(dw/2);

q0=qc0*p0-qc1*p1-qc2*p2-qc3*p3;

q1=qc1*p0+qc0*p1+qc3*p2-qc2*p3;

q2=qc2*p0-qc3*p1+qc0*p2+qc1*p3;

q3=qc3*p0+qc2*p1-qc1*p2+qc0*p3;

//

roll=atan2(2*(q0*q1+q2*q3),1-2*(q1*q1+q2*q2))*57.25977;

pitch=-asin(2*(q0*q2-q3*q1))*57.25977;

yaw=-atan2(2*(q0*q3+q1*q2),1-2*(q2*q2+q3*q3))*57.25977;

//

if(yaw<0)

{

yaw=360+yaw;

}

// 在串口输出陀螺仪的转动角度数据:

Serial.print(roll);Serial.print(",");

Serial.print(pitch);Serial.print(",");

Serial.print(yaw);Serial.print("///");

Serial.print(ax1);Serial.print(",");

Serial.print(ay1);Serial.print(",");

Serial.println(az1);

}

// 在程序中为了减少陀螺仪的数据误差,我们还需要在程序中加上陀螺仪的校准算法:

void getoffs()

{

int16_t ax, ay, az;

int16_t gx, gy, gz;

long int axsum=0;

long int aysum=0;

long int azsum=0;

long int gxsum=0;

long int gysum=0;

long int gzsum=0;

int i;

for(i=1;i<=2000;i++)

{

accelgyro.getMotion6(&ax, &ay, &az, &gx, &gy, &gz);

axsum=ax+axsum;

aysum=ay+aysum;

azsum=az+azsum-16384;

gxsum=gx+gxsum;

gysum=gy+gysum;

gzsum=gz+gzsum;

}

axoffs=-axsum/2000;

ayoffs=-aysum/2000;

azoffs=-azsum/2000;

gxoffs=-gxsum/2000;

gyoffs=-gysum/2000;

gzoffs=-gzsum/2000;

}

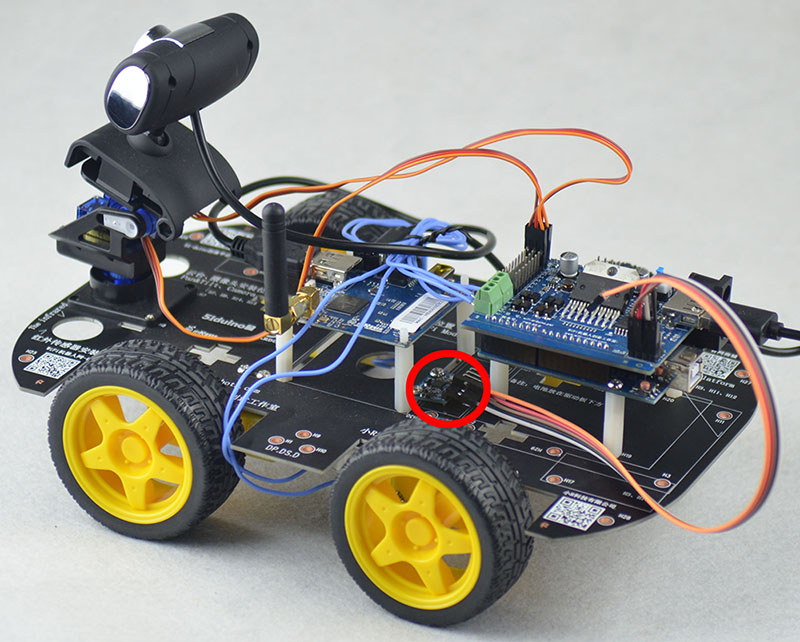

将程序写好以后,在Arduino 的IDE里编译并上传到Arduino的开发板上面,将陀螺仪连接到wifi机器人的小车上面(笔者用的是DS版),连通电源后开始测试。

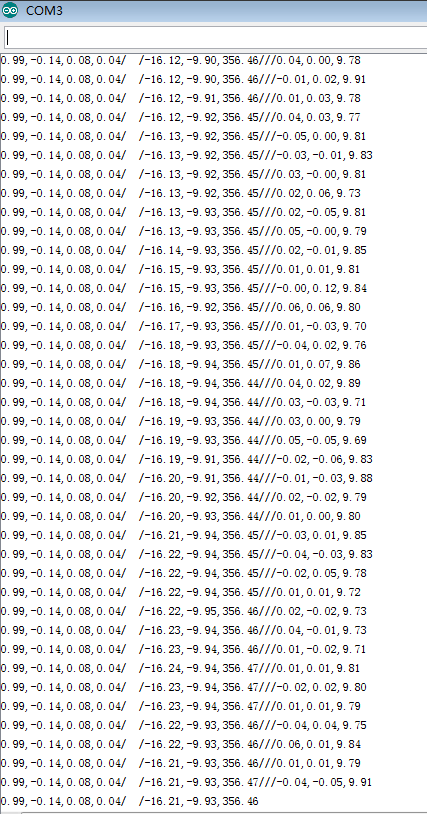

打开串口监视器,看看陀螺仪有没有正常运行,获得的角速度和计算出来的角度数据是否正确:

从图中可以看出,小车没有转动时,陀螺仪的角度数据基本上没有什么变化,说明陀螺仪的数据还是比较准确的。

大家可以根据这个程序来加以改进,获取更精确的数据,来更精确的控制小车的转动和运行。

网友评论仅供网友表达个人看法,并不表明 小R科技 Robots-Store机器人应用商城 同意其观点或证实其描述

昵称: 验证码: